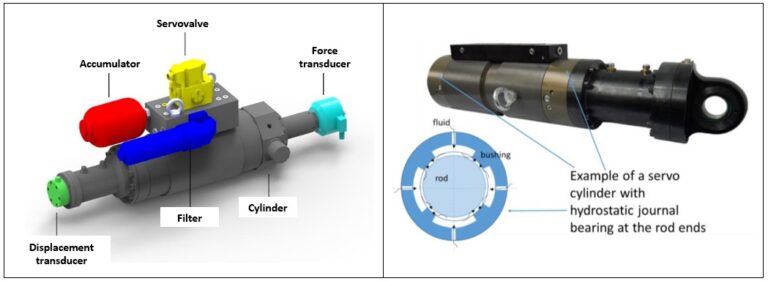

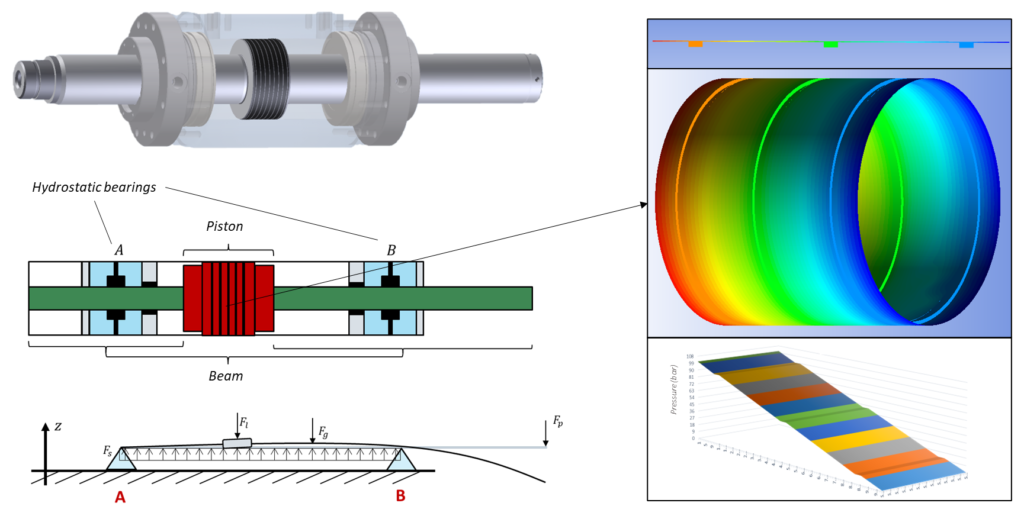

In the hydraulic servo-cylinders design, the circumferential grooves are used in order to reduce the effect of the locking force.

This force arises as a consequence to the distribution of pressure around the piston, when both an eccentric position, caused by the load on the piston, and the manufacturing defects on the piston and cylinder surfaces are present.

In this work, we present an approach for the calculation of the contribution of the grooves in the definition of the locking force and of the leakage flow rate.

The mathematical model proposed is based on the Reynolds equation, properly combined with the continuity equation applied within the grooves.

The results of the analysis are combined with the results coming from the analysis at the hydrostatic bearings at the rod ends, which have been analyzed on a previous step of the research.

A numerical procedure is then created that, with the appropriate input, allows to study the different design configurations of the servo-cylinder.

Results here in this paper are focused on exploring the effect of number, position, size of the grooves and manufacturing tolerances on the piston and cylinder (such as the piston taper and eccentricity). Simulations are also run under different operating conditions, such as pressure, cylinder velocity and oil temperature

For the real servo-cylinder configurations tested in this work, it is shown that five equally spaced grooves may be sufficient to decrease consistently the locking force while containing the flow losses.

The procedure is also functional to investigate the bending and seizing of the piston during the different operating conditions, both in steady state and dynamic conditions.